Tucson Knife Sharpening Service

My sharpening services are available through these options:

Forbes Meat Company drop-off every first weekend (next: 2/29-3/1)

Drop your knives off Saturday or Sunday of the first weekend of every month, they’ll be finished and ready for pickup at Forbes on Wednesday (they’ll take care of the payment). Please make sure they’re transported safely (wrapped up individually, in a block, or in a knife roll).

Pick-up for orders over $100

I can come to your restaurant, pick up the knives, and have them dropped back off the next day.

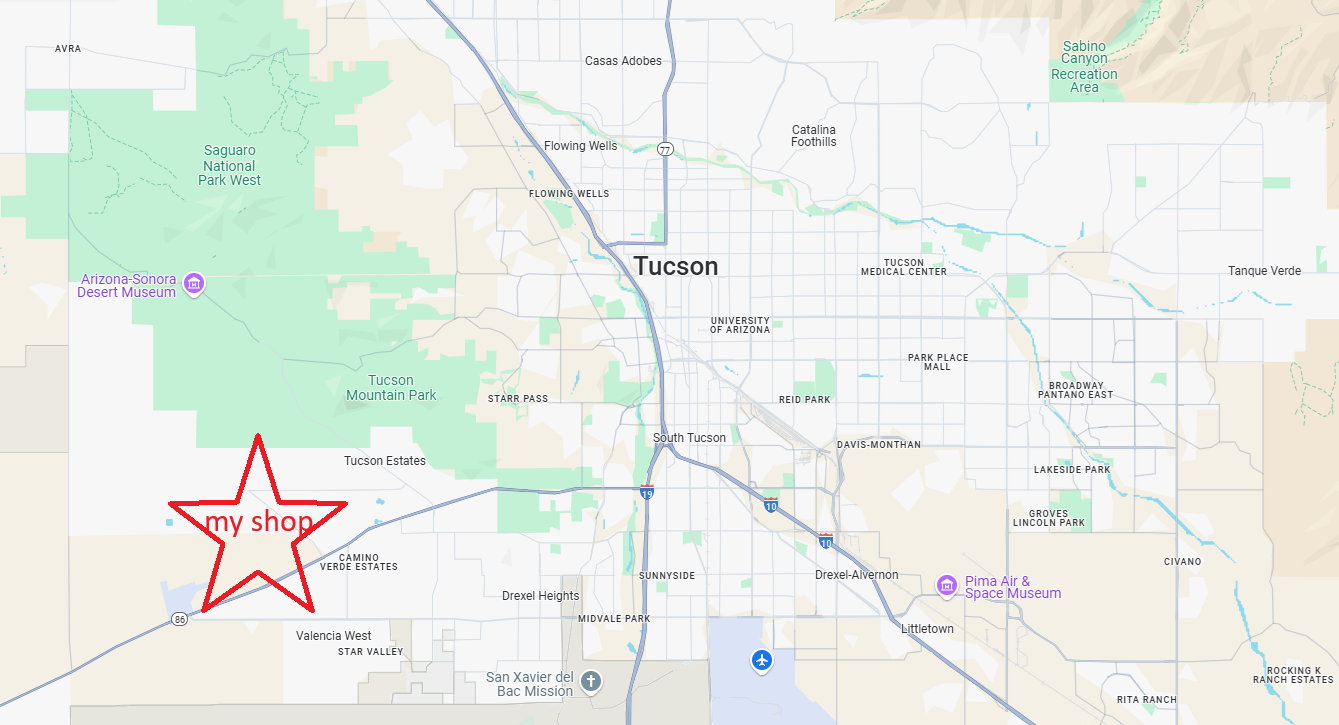

Drop off to my shop location (on the West side)

Please send me an email at don@donnguyenknives.com to schedule a drop-off or a pick-up. My shop is out on the West Side of Tucson, near Bopp and San Joaquin.

Pricing:

Double Bevel Sharpening

$2.5/inch (20% discount rate for restaurant pickup service)

$10 minimum on all knives (ex. 2” parer = $10)

Japanese Single Bevels

starting at $4/inch

Serrated Knives or Shears (if I am able to accomodate them)

$4/inch

Tip Repairs (greater than 5mm or ~0.20”)

$5

Chip Repairs (greater than 2mm or ~0.08”)

$10

Spine and Choil Rounding (making the blade comfortable to hold)

$10

Thinning (see below for details)

$50

Small tip/chip repairs I just take care of at no additional cost. For any outliers (large repairs) I will discuss those individually.

For sharpening orders,

In most cases I can have the knives sharpened up and finished by the next day.

How do I know you’ll do a good job, and not take off too much material, or burn the temper of the steel?

I suppose it is a leap of faith, but I hope to show through this Q&A that I care about my craft and I always do my best for the knives. I specialize in making high-end kitchen cutlery full-time, I have a good feel for kitchen knife performance and sharpening, and I really care about the Tucson community.

Through making my own knives, I’m pretty intimate with the process of taking off material at the edge without burning it. It’s one of the most difficult skills in the job, but it’s the most critical one to make sure a knife actually performs well. I also have a good sense for how much material to take off - thin enough to cut well, acute enough for the steel to be able to support that edge, and just enough to raise a small burr and reestablish the edge. I have a YouTube channel that showcases a lot of my knife-making process.

How do you sharpen them? Do you use stones, or machines?

For high-end knives that have generally harder steel and thinner geometry, I will sharpen them all by hand with waterstones. For most other knives I use a combination of my disc sander and the stones.

The disc sander is the ultimate tool in my shop; it IS a motorized device, but it has the same muscle memory as hand sharpening, I can swap between any grit I want, and I also saturate the abrasive with water to keep things cool. It’s efficient and has great control, which allows me to establish a cleaner, more consistent edge than any belt grinder out there. I use it for making every single knife in my shop and I can’t live without it.

Disc Sander

Waterstone

What angle and grit do you sharpen to?

It depends on the knife and I go by feel for each one. Depending on the steel, the geometry, and how thin it is at the edge, I’ll adjust my angle and grit to that.

For a knife that has harder steel and thinner geometry I’ll go acute on the angle, approximately 8 to10 degrees, and go higher grit. These knives can support that geometry better and hold that edge for longer.

For a knife with softer steel, I’ll raise that angle slightly, anywhere from 13 to 18 degrees, depending on how the steel and geometry feels.

Softer Steel

Hard Steel

How long will the edges last after sharpening?

The variables that affect how long the edge will last include: the steel and heat treatment of the knife, its edge geometry, the cutting board used, what food product is being cut, the cutting style, and how they're cleaned and stored.

For example, I cook with mostly simple carbon steel knives and I only sharpen them about once a year (and truthfully they're sharpened for demo purposes in my knife making classes). The edges last a long time because the knives have good steel and heat treatment, I use wood and rubber cutting boards, I don't bang them aggressively during cutting, and I make sure I clean and store them safely so that the edges never make contact with any hard objects.

Knives with softer steel may not last as long and will require more frequent touch-ups and sharpenings, but the maintenance is the most important part (maintenance tips here).

Knives that are improperly maintained will probably only last a week, regardless of what kind of knives they are. If that edge hits random objects in the sink, dishwasher, or drawer, it will dull immediately.

What is thinning, should I do it, and how do I know if I should?

Thinning is the process where I remove material behind the edge and make the geometry, well, thinner. This is arguably the MOST effective modification that can be done to make a knife perform better; it’s also the most labor intensive. Sharpness is only the first variable to cutting performance, geometry affects everything after the edge initiates the cut.

If your knife cracks potatoes instead of cutting and sends carrots across the room (even with a sharp edge), it probably can be thinned. If a knife takes a LONG time to sharpen, it could mean it might need thinning (more surface area to sharpen means it takes exponentially longer).

Most factory knives are manufactured with a high factor of safety to begin with, so their geometries are already thick (which is why I encourage proper maintenance instead of just replacing them) - after years of use, honing, and sharpening, the material right behind the edge gets thicker and thicker.

Note that after thinning the blade finish will NOT be factory original, but it most likely will cut better than it has ever before.

Cross Section Before

Cross Section After

Thinned Blade Finish

Factory Blade Finish

What do you do with full bolsters?

Those bolsters are an absolute abomination and a disgrace to kitchen knife designs. They get in the way of sharpening and practically every knife with a bolster develops an overgrind at the heel over time from honing and sharpening.

I grind the bolsters down at the heel and true the profile of the edge back up.

How should I transport my knives to you?

Anything that protects the edge can work. A knife block, knife roll, knife cases, or individually wrapped up (towels and rubber bands for example, not all loose together) all can work.

As long as the edges are protected and it’s safe, it will work! Please do not hand me a pile of loose knives.